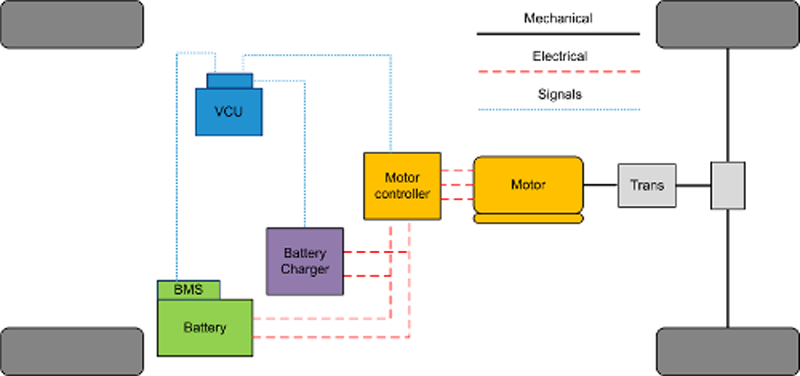

Motor controller is a device that improves the performance of an electric motor in a prearranged manner. Motor controllers can include an automatic or manual means for starting/stopping the motor, choosing forward/reverse rotation, selecting and controlling the speed, modifying or limiting the torque, and shielding against faults and overloads. The major constituents of electric vehicle systems are the motor, power supply, controller, drive train and a charger. An EVM controller or electric vehicle motor controller is a machine that is employed to regulate the torque generated by the motors of electric vehicles by means of modifying the energy flow from the power sources to the motor.

- Similarities and differences with ICE

- Components and key performance criteria

- Transmission and Power Couplings- AMT, Dual Clutch, CVT

- Shift Quality Parameters

- Converters

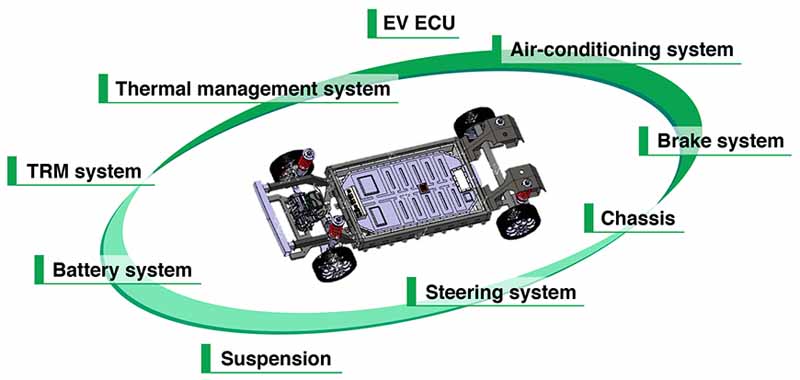

- Architecture Development of EV's:

- System Integration -Dynamics-Topology Selection & Modeling, Braking, Safety

- Range / Power conflict

- Regenerative Braking System

- Thermal Management for Motors & Batteries:

- Thermal Issues & Functions of Thermal Management System

- Technologies for Thermal management Air Cooling, Liquid Cooling

- Direct Refrigerant Cooling, Thermos Electric Module

- Existing EVs Architecture

- Live discussions of Hero Electric, Mahindra E2O, Ather Energy, Okinawa praise, gogoro electric scooter.

EV

Purely electrical vehicles use an electric motor for traction, and batteries for their corresponding energy sources. The EV has many advantages over the conventional internal combustion engine vehicle, such as absence of emissions, high efficiency, independence from petroleum, and quiet and smooth operation.

Motor and its control technology are one of the main components of Hybrid Electric Vehicle (HEV). To meet HEV's fast torque response, vector control algorithm based on rotor flux-oriented and simulation model is concerned and modular designs for controller's hardware and software are presented in the paper in order to build a platform to achieve the vector control of asynchronous induction motor. Analyze the controller's electromagnetic compatibility, introduce the corresponding antijamming measures to assure the normal operation of the electromagnetic sensitive devices such as CAN bus; experiment proves that the measure is practical and feasible. On the basis of the control logic correct, such as improving CAN bus communication reliability, assuring power-on sequence and fault treatment, carry on the motor bench experiment, test its static properties, and adjust the controller parameters. The experimental results show that the designed driving system has the performance of low speed and high torque, a wide range of variable speed and high comprehensive efficiency.